Spark Plug Wire Technology

Posted by Scott's Performance Wire on Dec 28th 2022

30+ years of motorsports and high performance technology - Top Fuel and NASCAR Cup Series tested Performance and quality standards unsurpassed in the industry

At Scott Performance Wire our engineering team has been innovating wire technology for over 30 years. With a strong background in motorsports and high performance OEM engine manufacturing, our team works every day to provide our customers with the highest performing ignition wire products in the industry. Each of our wire sets is hand made and individually tested before leaving our manufacturing facility. Each wire must pass an impedance test, a sample wire/terminal is pull tested (before set is produced) and each terminal crimp is measured and recorded. Our wire products are made specifically for each of our applications and can be custom configured for any of your spark plug wire needs.

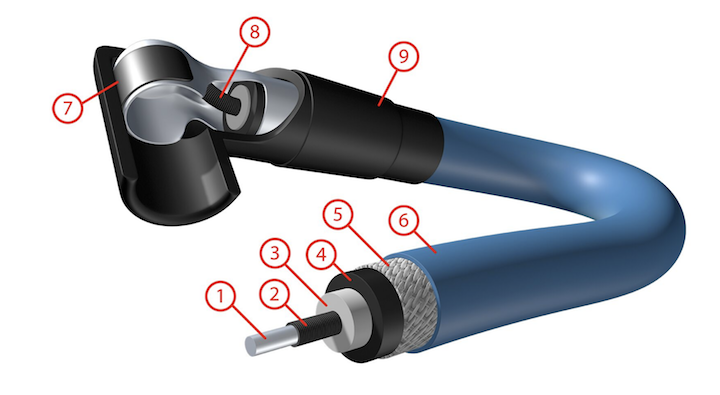

1. Fiberglass/Aramid (Kevlar®) Blend Ferrite Coated Core

2. Stranded Alloy - TPI (Turns P/Inch) Determined by Wire design

3. Silicone Inner Core for Strength, EMI/RFI Control and Break-down Voltage

4. Silicone Outer Core for Abrasion and Heat Resistance

5. Fiberglass Sleeving Rated @ 1000˚F

6. Additional Silicone Sleeving on Scott Wires Provides Added Protection Against Heat and Abrasion

7. Stainless Steel "Snap-Lock" Tab for Positive Lock to Spark Plug

8. Bend Crimp for Ultimate Termination

9. High Temp Silicone Boot and Heat Shrinks for Added Protection